|

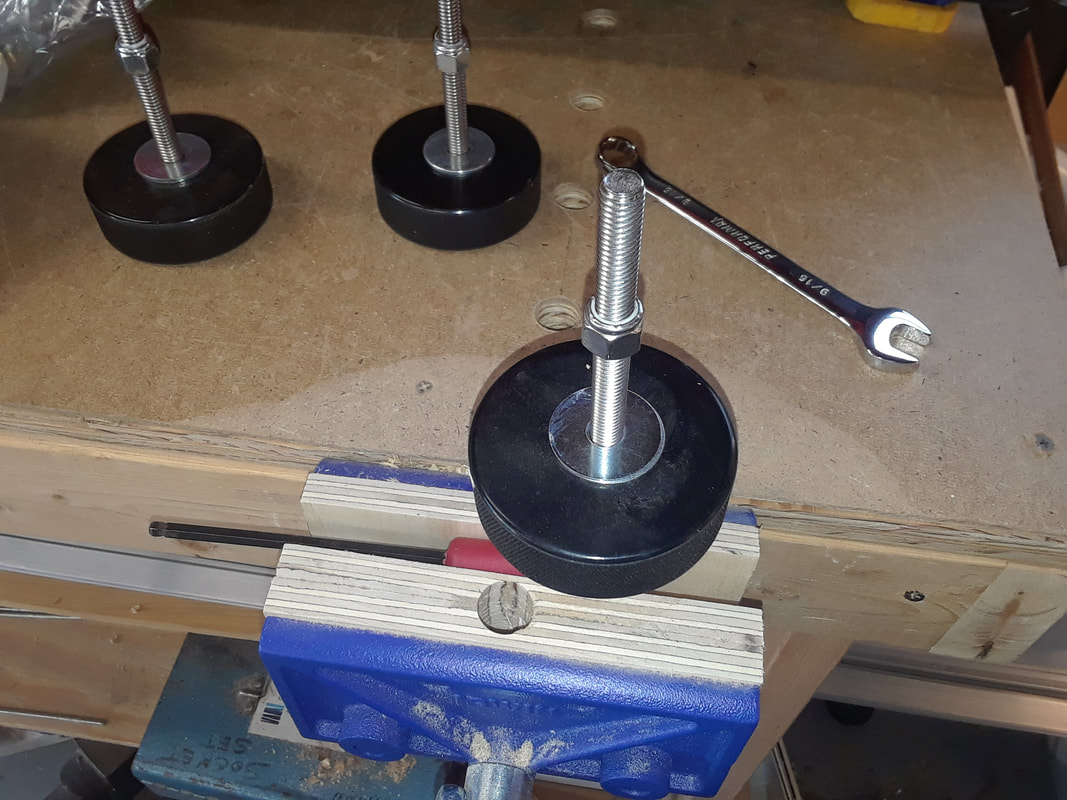

Was tired of my workbench sliding everywhere and not being perfectly level so I made some custom adjustable feet for them. Taking some hockey pucks I drilled a recessed hole in the center of them for some bolts. Clamping a hex key in the vice to make assembly easier...  On go two washers and a Teflon nut. A second Teflon nut and two washers go on to help support the leg once it is set to the correct height,  Had to fix the threads on a bolt so used a bolt file to fix it. Will be doing a video on Bolt Files this winter! Six little legs ready to install!!!

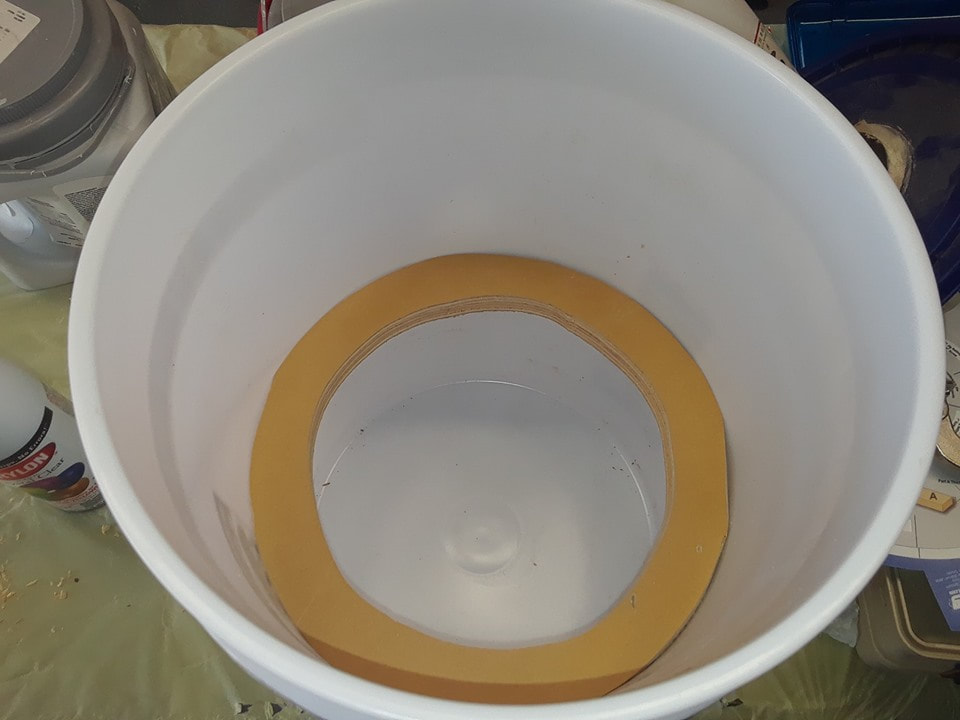

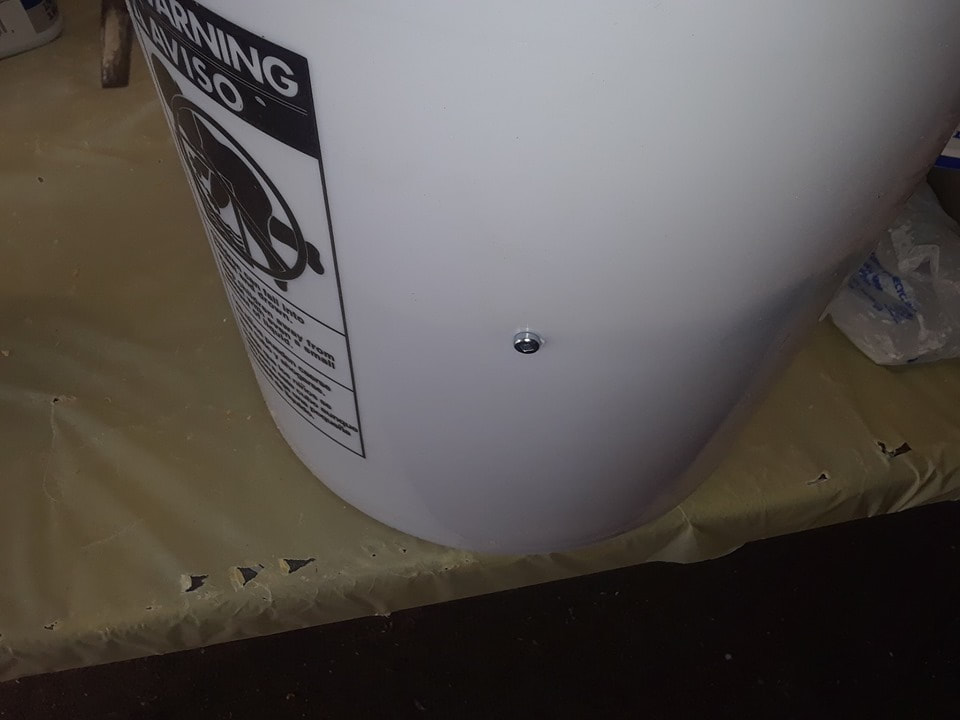

More to come! With how much the shop vac is used, the filter and filter bag contently needs cleaned to provide good suction. So to remedy that, I am finally adding on a cyclone extractor before the main vacuum chamber. This will keep the filter cleaner longer and provide better function and easy of cleaning the bins. First I take a 5 gallon bucket and add a wooden ring half way up on the inside. this helps to keep the bucket from getting crushed should the hose get clogged while running. The wood ring is secured from the outside via some Kreg screws and then sealed with some window caulking. Using some scrap MDO I cut a doughnut to fit the bucket with a lip big enough to cut holes in later to store accessories. While I was at it I upgraded the hardware on top of the Vac itself to take the weight of the extra load on top of it. It may not look pretty but it works great. It also does not take up any extra floor space. I few more add-ons and an extra bracket for good measure and it will be done!

|

Categories

All

Archives

October 2023

|

RSS Feed

RSS Feed