|

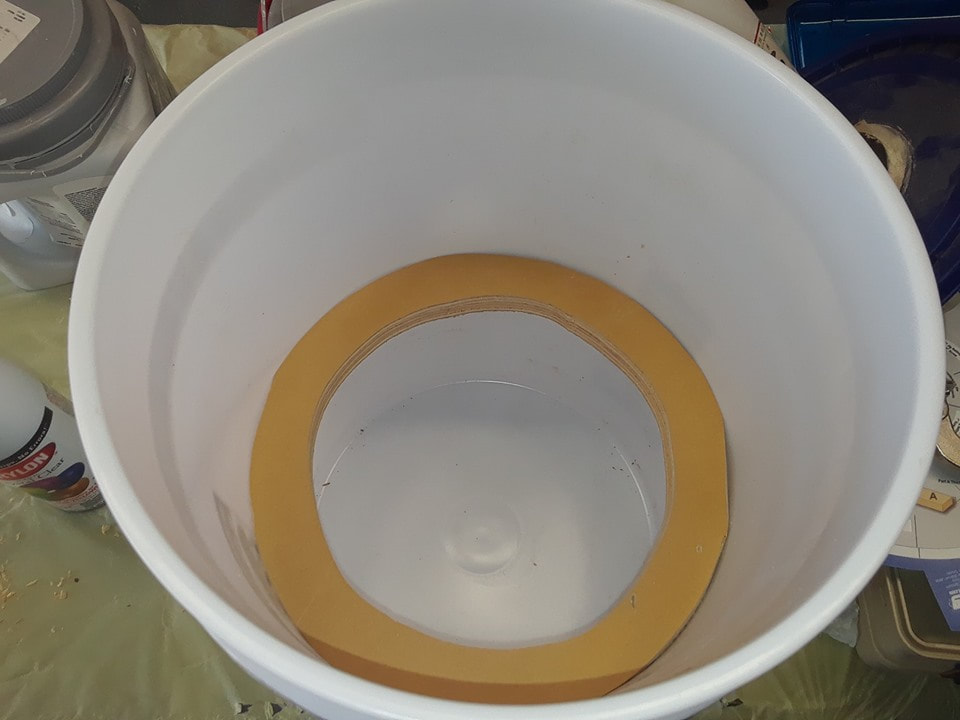

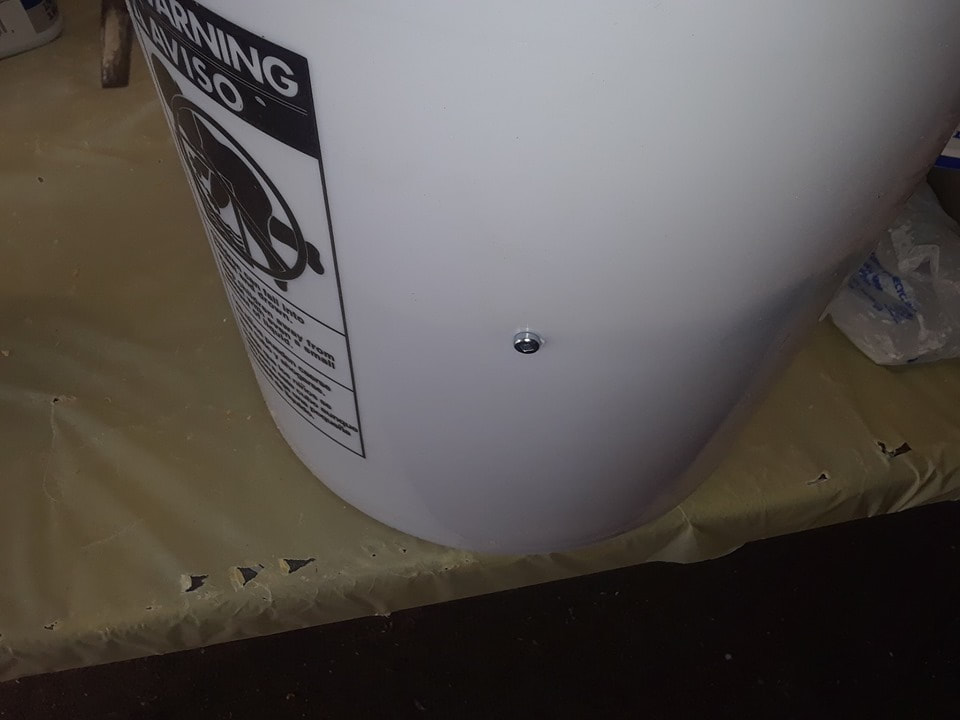

With how much the shop vac is used, the filter and filter bag contently needs cleaned to provide good suction. So to remedy that, I am finally adding on a cyclone extractor before the main vacuum chamber. This will keep the filter cleaner longer and provide better function and easy of cleaning the bins. First I take a 5 gallon bucket and add a wooden ring half way up on the inside. this helps to keep the bucket from getting crushed should the hose get clogged while running. The wood ring is secured from the outside via some Kreg screws and then sealed with some window caulking. Using some scrap MDO I cut a doughnut to fit the bucket with a lip big enough to cut holes in later to store accessories. While I was at it I upgraded the hardware on top of the Vac itself to take the weight of the extra load on top of it. It may not look pretty but it works great. It also does not take up any extra floor space. I few more add-ons and an extra bracket for good measure and it will be done!

0 Comments

Today I finally did a little something about the dust in the shop as well as getting some air circulation on a hot day. I installed two box fans with house filters on top that help to alleviate most of both problems. Box Fan.... amzn.to/2IY0aXj Filters..... amzn.to/2s1Tg9y First I measured the box fan, it came out to 20 and a half inches. The space between the rafters is 22 and a quarter. So by adding a filler 2x4 gives me the correct spacing to attach the fan between two rafters. Next I temporarily attached a helper board with some clamps to help hold the fan up while I attached it to the rafters. Clamps........ amzn.to/2s1OyIZ Taking the front screen off I drilled 4 holes, two on opposite sides that the screws go through to fasten to the beams. After being secured I took down the helper board and put the front grill back on. I then put the 20x20 filters on top facing the correct direction and put two pieces of painters tape on each fan to hold them in place when the fans are not running.

Have had this shop vac for over 10 years now. Got it used, but it never had a complete handle so I rummaged through my scraps today finally and found some aluminum and PVC fittings. I drilled corresponding holes in the aluminum so the push button releases work if I ever need them too. The PVC handle is screwed to the new aluminum rail. Now I can tilt the vacuum back properly when I need to wheel it about. Part two will be attaching the vortex bucket to the system so my filter does not clog up with the fine dust.

|

Categories

All

Archives

October 2023

|

RSS Feed

RSS Feed